As energy efficiency becomes a top priority across industrial and commercial sectors, every component in an electrical system matters. While major equipment often gets the spotlight, smaller devices play a critical role in ensuring safety, reliability, and efficiency. One such essential component is the switch disconnector.

Understanding the function and benefits of switch disconnectors is key to designing and maintaining robust electrical infrastructures. These devices are fundamental to safe operations, allowing for the complete isolation of circuits for maintenance and preventing costly downtime. This guide will explore what switch disconnectors are, how they contribute to energy efficiency, and why they are indispensable in today’s demanding electrical environments.

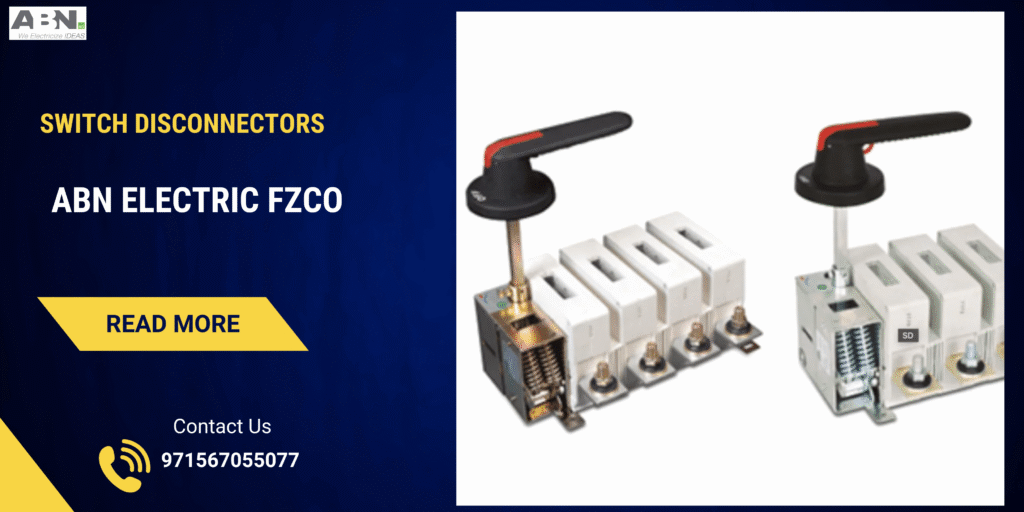

What Are Switch Disconnectors?

Switch disconnectors, also known as isolator switches, are mechanical devices designed to safely de-energize an electrical circuit from its power source. Their primary function is to provide a visible and verifiable break in the circuit, ensuring that downstream equipment is completely isolated before maintenance or repair work begins. This isolation capability is a fundamental safety requirement in any electrical installation.

Unlike a circuit breaker, which is designed to automatically interrupt a circuit during an overcurrent or short-circuit event, a switch disconnector is typically operated manually. Its purpose is not to protect against faults but to guarantee that a section of an electrical system is safely powered down. This makes them a crucial element for protecting personnel and equipment.

Key features often include:

- Visible Break: Many designs offer a clear visual indication that the contacts are open, providing an extra layer of safety confirmation.

- Padlock Facility: The ability to lock the switch in the “off” position prevents accidental re-energization while work is in progress.

- Durability: Built for frequent operation, they feature robust construction to withstand the mechanical stress of switching.

The Importance of Switch Disconnectors for Safety

Safety is the foremost reason for installing switch disconnectors. Working on energized equipment can be fatal, and these devices provide a reliable method to create a safe working environment. By completely isolating a circuit, they eliminate the risk of electric shock and prevent accidental startup of machinery.

In industrial settings, regulations like OSHA’s Lockout/Tagout (LOTO) standards mandate procedures for controlling hazardous energy. Switch disconnectors are central to complying with these regulations. The door interlock and padlock facilities found in quality switch disconnectors ensure that access to energized parts is restricted and that the circuit cannot be reconnected until all maintenance is safely completed. This makes them a non-negotiable component for any facility committed to workplace safety.

How Do Switch Disconnectors Enhance Energy Efficiency?

While their main role is safety, switch disconnectors also contribute to creating more energy-efficient electrical systems in several important ways.

Minimizing Standby Power Consumption

Many machines and systems consume a small amount of power even when they are not in active use. This is often referred to as “vampire” or “standby” power. While the draw from a single piece of equipment may be minimal, the cumulative effect across a large commercial or industrial facility can be substantial, leading to wasted energy and higher utility bills.

By using switch disconnectors to completely isolate equipment from the power supply, facilities can eliminate this standby power consumption entirely. This is particularly useful for machinery that is shut down for extended periods, such as overnight, on weekends, or during scheduled production halts.

Reducing No-Load Losses in Transformers

Transformers experience “no-load losses” whenever they are energized, even if they are not supplying power to a load. These losses occur due to the magnetization of the transformer’s core. In large facilities with multiple transformers, these continuous losses can add up to a significant amount of wasted energy.

Placing a switch disconnector on the primary side of a transformer allows it to be completely de-energized when the downstream load is not required. This simple practice can lead to considerable energy savings, especially in applications where loads are intermittent.

Improving Power Quality and System Stability

Efficient energy use is not just about reducing consumption; it’s also about maintaining high power quality. Switch disconnectors help by enabling planned and sectionalized maintenance. A well-maintained system operates more efficiently, with fewer unexpected failures and less energy wastage.

Regular maintenance, facilitated by the safe isolation provided by switch disconnectors, ensures that all components are functioning at their optimal level. This prevents issues like overheating connections or degraded components, which can lead to energy losses and potential system instability.

Selecting the Right Switch Disconnectors

Choosing the correct switch disconnector is vital for ensuring both safety and efficiency. Several factors must be considered during the selection process.

Electrical Ratings

The device must be rated for the system’s voltage and current. The rating should be sufficient to handle the full load current of the circuit it is intended to isolate. For instance, switch disconnectors come in a wide range of ratings, from 25A to over 3150A at 415V, making them suitable for diverse applications.

Number of Poles

The number of poles (2P, 3P, 4P, etc.) must match the requirements of the electrical circuit. Three-phase systems typically require 3-pole or 4-pole switches. Modular pole designs offer an economic advantage for maintenance, allowing individual poles to be replaced if needed.

Enclosure and Mounting

The environment where the switch will be installed determines the required type of enclosure. Switch disconnectors are available in open versions for installation within panels or with sheet steel enclosures for standalone mounting. Features like a telescopic shaft for depth adjustment can simplify installation in various panel configurations.

Compliance with Standards

Ensure the selected device complies with international safety standards. This guarantees that the product has been tested for reliability and performance, providing peace of mind that it will function correctly when needed most.

Essential Components for Future-Ready Systems

As organizations continue to seek ways to reduce their carbon footprint and operating costs, optimizing energy use is more important than ever. While smart grids and renewable energy sources are significant parts of this transition, fundamental components like switch disconnectors provide the practical foundation for an efficient and safe electrical system.

By integrating high-quality switch disconnectors into your electrical design, you can effectively manage energy consumption, enhance system reliability, and, most importantly, ensure the safety of your personnel. They are a small but powerful tool in the larger strategy of building sustainable and efficient operations.