Capacitor duty contactors play a crucial role in industrial and commercial facilities that rely on power factor correction and reactive power management. If you’re searching for clarity on how to size these contactors properly to suit your specific power needs, you’re not alone. However, the good news is that correctly sizing a capacitor duty contactor doesn’t have to be complicated when you’re armed with the right knowledge and resources.

This blog is designed to guide electrical engineers, plant managers, and facility engineers through the process of sizing capacitor duty contactors effectively. We’ll explore key factors that influence sizing, share practical steps for selecting the right contactor, and help ensure optimal power performance for your facility.

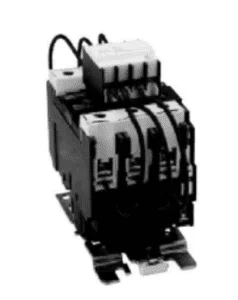

What Is a Capacitor Duty Contactor?

A capacitor duty contactor is a specialized type of contactor specifically engineered to handle the tasks associated with power factor correction and reactive power compensation. Unlike standard contactors, they are designed to handle the inrush current that occurs when power capacitors are energized. These heavy-duty devices ensure that your capacitors are switched safely and effectively, increasing the stability of your electrical system and extending the lifespan of essential components.

Why Is Proper Sizing Important?

Using an improperly sized capacitor duty contactor leads to several issues, including

- Excessive inrush currents damaging the contactor or capacitors.

- Inefficient power factor correction.

- Increased downtime due to equipment failure.

- Higher maintenance and energy costs.

Getting the sizing right ensures your electrical system operates efficiently, reduces wear and tear on equipment, and saves you headaches (and dollars) in the long run.

Key Factors to Consider When Sizing Capacitor Duty Contactors

To properly size a capacitor duty contactor, there are several parameters you’ll need to evaluate. Each of these factors plays a crucial role in selecting the best-fit contactor for your system:

1. Reactive Power Rating (kVAR)

Your system’s total reactive power requirement, measured in kilovolt-amperes reactive (kVAR), serves as the foundation for determining the contactor size. This refers to the amount of power needed to improve the power factor, and capacitor duty contactors are rated to handle specific kVAR levels at a defined voltage.

For example, if your power factor correction system needs 50 kVAR at 415V, the contactor you select must be capable of handling this load without failure.

2. Operating Voltage

Voltage ratings must match your network’s requirements. Capacitor duty contactors are usually rated for voltages like 230V, 415V, or 690V. Ensure that you consider the line voltage and verify the contactor’s compatibility with your system to avoid underperformance or damage.

3. Current and Peak Switching Capability

Capacitor duty contactors face significant inrush currents when engaging the capacitors. These inrush currents can be 100-200 times greater than the rated current. Therefore, check the manufacturer’s specifications for peak switching capability to verify that the contactor can handle the initial surge of current without experiencing wear, welding, or other failures.

4. Number of Steps in the Capacitor Bank

If your power system uses a capacitor bank with multiple steps, you’ll need a contactor capable of switching individual steps efficiently without overloading. Each step may need a separate contactor, or you might look into models that support multiple steps.

5. Operating Temperature and Environmental Conditions

The operating environment, including ambient temperature, humidity, and exposure to dust or vibration, also affects the durability of capacitor duty contactors. Ensure your chosen contactor includes adequate protection (such as IP ratings or cooling systems) to thrive in your specific environment.

6. Manufacturer Recommendations

Each manufacturer designs capacitor duty contactors according to certain standards. Always consult the manufacturer’s product specifications for guidance on matching the contactor to your kVAR and voltage requirements.

Step-by-Step Guide to Properly Sizing a Capacitor Duty Contactor

Now that we’ve covered the essential factors to consider, here’s a step-by-step breakdown for sizing capacitor duty contactors for your facility:

Step 1: Assess Total kVAR Requirements

Evaluate the total reactive power (kVAR) your system requires. This information is often provided in system designs or can be measured using power-factor correction strategies.

Step 2. Confirm Voltage and Frequency

Identify the operating voltage and frequency of your facility’s electrical system. Be sure that the contactor’s voltage rating matches your requirements exactly.

Step 3. Calculate Peak Switching Currents

Use manufacturer-provided guidelines or formulas to estimate the inrush current and peak switching currents of the capacitors. This calculation ensures the contactor can withstand the initial surge.

Step 4. Match kVAR and Current Ratings to Contactor Specifications

Review capacitor duty contactors available on the market and match their kVAR, current, and voltage specifications with your facility’s requirements. Look for options specifically rated for heavy-duty capacitor switching applications.

Step 5. Verify Safety Margins

Always select a contactor with a margin of safety above the calculated requirements (e.g., a 10-15% margin for current). This reduces wear-and-tear from sustained inrush currents and enhances long-term performance.

Step 6. Consult Experts or Resources

When in doubt, consult your vendor or an experienced supplier to ensure proper sizing. Resources like ABN Electric offer valuable insights and detailed product options for choosing the right capacitor duty contactor for your application.

Common Mistakes and How to Avoid Them

Even experienced engineers or plant managers occasionally make errors when sizing capacitor duty contactors. Here are a few common mistakes and tips on avoiding them:

- Ignoring Temperature Ratings: Be sure to account for environmental conditions that could impact functionality and lifespan.

- Underestimating Peak Currents: Always confirm peak current capabilities to avoid operational stresses on the contactor.

- Overloading Contactors: Avoid using a contactor at its absolute maximum rating. Always incorporate a safety margin to extend its life and ensure dependability.

The Value of Properly Sized Capacitor Duty Contactors

Proper sizing of capacitor duty contactors is not just a matter of technical precision; it’s directly tied to the efficiency and safety of your facility’s power system. A well-sized contactor saves energy, minimizes wear on your power network, and delivers seamless power factor correction.

Upgrade Your System’s Performance

Sizing capacitor duty contactors might take some effort, but the results can profoundly affect your facility’s cost savings, efficiency, and long-term reliability. Whether you’re optimizing power factor, reducing energy costs, or ensuring safer operations, the right contactor is key.

If you’re ready to streamline your system’s performance, explore ABN Electric for capacitor duty contactors tailored to meet the most demanding industrial applications. Contact us today for expert advice and product recommendations!